REPAIR

With our essential repair service for our distributed brands, your products are fully supported. With authorization by our manufacturers, we use authentic procedures and parts for our repairs to ensure optimal functioning of all components. We also apply the manufacturers' warranties when necessary.

Diagnosis and Reports

We have the knowledge and equipment to provide an accurate diagnosis and make any necessary repairs.

Repairs of Distributed Products

Our focus is to serve our distributed brands as best as possible, which is why we offer robust repair services for our products.

Manufacturers’ Warranties

As an authorized service center for major lines, such as Danfoss and Eaton, we have the ability to enforce product warranties.

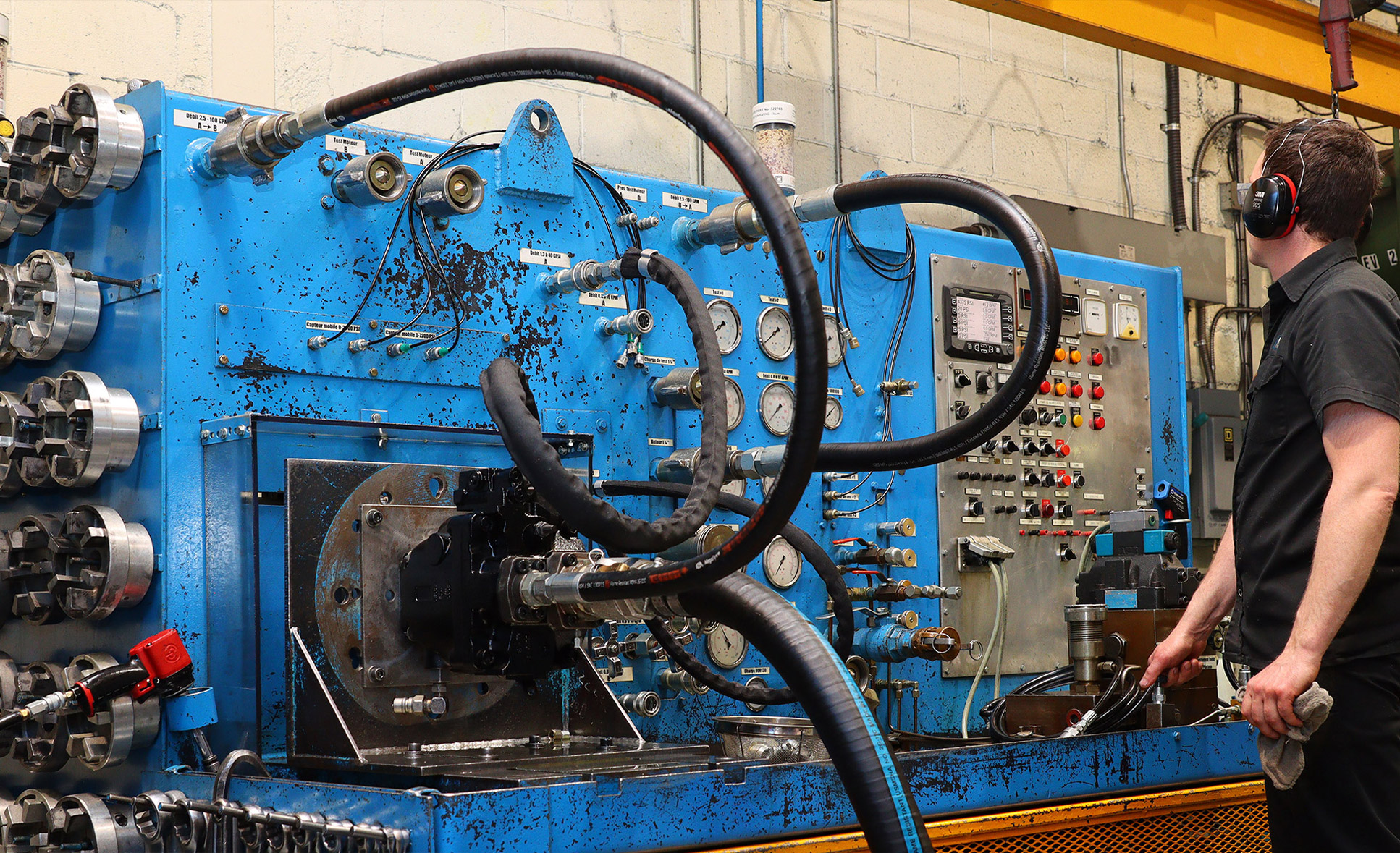

Tested and Adjusted

Each of the components we repair are thoroughly tested and adjusted according to manufacturers' specifications. We use many test benches, including 150HP.

Certified Technicians

Our technicians are trained according to the standards of our suppliers and have access to all the technical documentation necessary for repairs and assembly.

Reconditioning of Components

Our repair service uses original parts to recondition your components, a smart way to restore them to their original performance without the need for a complete replacement.

Authorized Repair Center

Our repair service technicians are authorized by the manufacturers, ensuring that all work is performed according to the rules of the trade and in such a way as to maintain your guarantees in force.